Research and Learning Objectives

The goal of the REACH REU summer undergraduate research program is to build on longstanding strengths in fundamental physics and chemistry of metal combustion, coupled with cutting edge synthesis and manufacturing techniques, to provide new scientific insight resolved under in-situ combustion conditions not fully investigated.

The projects highlighted below propose to study a range of metal-based energetics under a variety of combustion conditions to improve their contribution to energetic systems, and provide avenues for translating research results to practice. The representative projects are presented in scaling order to demonstrate how students will be able to investigate questions spanning SYNTHESIS of new novel high energy density metallized materials (Aning, Schulz, Liu, Bortner), DIAGNOSTICS & EXPERIMENTS (Jacques, Young, Seidel) for understanding the energy release processes of these materials, and MODELING & MACHINE LEARNING (Massa, Lowe, Sarlo) to support theory and simulation of energy release mechanisms.

TRACK 1: Metallic Materials and Polymer Composite Synthesis for Controlled Energetic Release

Dr. Alex Aning, Material Science and Engineering

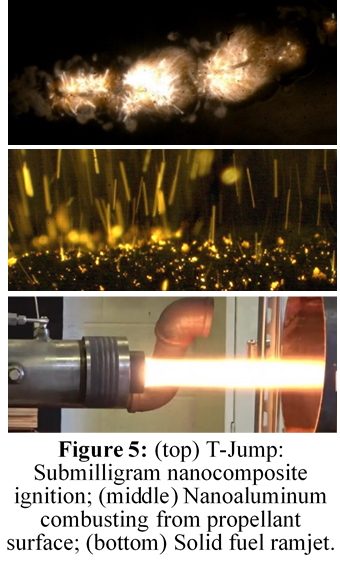

The Aning Group at Virginia Tech specializes in mechanochemical powder metallurgy and application of internal friction to the study of phase transformations in metallic solids. Metastable metallic alloys are high energy density composites that have been repeatedly cold-welded and fractured through continuous ball-powder collisions in arrested reactive milling (ARM). REU researchers will probe the influence of different milling parameters and combinations of precursor metals on the composition, crystalline structure, and ignition temperature of metastable alloys. Beginning in Summer 1 with micron-sized powders of Al, Mg, B, and Ti, select combinations of Al-Mg, Al-B, B-Mg, or Ti-B alloys will be processed using ARM. The milling process will be interrupted as close to the initiation of the self-sustained exothermic reaction time as possible. Milling parameters will then be correlated to the morphology, particle size, and mass agglomeration of the new mechanically alloyed powders, characterized by FE-SEM and X-ray diffraction at the Virginia Tech Nanoscale Characterization and Fabrication Laboratory (NCFL). Beginning in the first summer and continuing in Summer 2, once suitable compositions have been identified and prepared, the ignition temperatures of the metastable alloys will be characterized using the T-jump test and optical pyrometry (partnering with Lowe and Young). At this point, a complete picture of the influence of milling parameters and composition on the morphology and kinetics of metastable alloys will begin to emerge at the milligram scale. Summer 3 will focus on bulk scale performance characterization of select powder compositions as a replacement to elemental aluminum fuel grains in solid rocket propulsion (partnering with Schulz and Liu for polymer binders, Young for evaluation) and multiphase detonation (Jacques). These progressively more complex and integrated projects are well-suited for entry-level researchers who will develop expertise the science, processing, characterization and properties of reactive metals and their integration into energetic systems.

Dr. Michael Schulz, Department of Chemistry

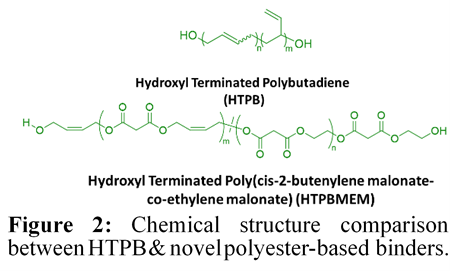

Despite being integral to many rocket propellant formulations (Hunley 1999), hydroxy-terminated polybutadiene (HTPB) has critical issues in its mechanical properties and processability, as well as contributing little to the energetic output of the propellent (Zhang et al. 2019[JE1] ). “Energetic binders” have been developed to address this second issue, but while successful in some regards, these materials often have reduced mechanical properties (Ang and Pisharath 2012). In this project, we take an intermediate approach by developing inert binders with mechanical properties similar to or better than HTPB-based binders, but with improved oxygen balance to ultimately improve the contribution of these new binders to the energetic output of the formulation.

Like traditional formulations, we will develop segmented polyurethanes as binders due to the advantageous mechanical properties of this class of material. Our key innovation will be in the soft block (Figure 2): Rather than using HTPB we will use polyesters made by copolymerization of cis-2-butene and various aliphatic diesters, leading to materials with properties analogous to HTPB, but with higher oxygen content (Ang and Pisharath 2012). Additionally, the more polar functional groups of these new materials will interact more strongly with the metal particles, metal oxides, or explosive crystals, potentially leading to enhanced combustion characteristics of the overall composition. REU students will gain experience in fundamental polymer chemistry as they synthesize new polymer binders, and collaborate with students working in other labs studying the rheology and 3D printability (Bortner group), and combustion (Young group) of resulting formulations.

Dr. Greg Liu, Department of Chemistry

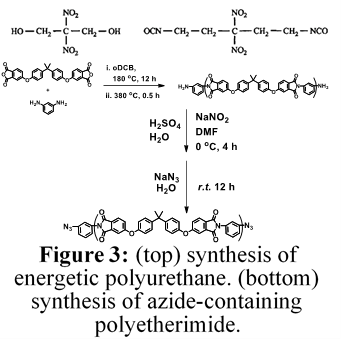

Energetic materials often desire the use of energetic polymers as binders in terms of both performance and safety. On the one hand, polymers can be directly used as energetic materials, when energetic moieties such as nitro (NO2), nitrate (NO3) or azide (N3) are present. On the other hand, they can be used as a matrix in a polymer composite to enclose energetic materials and ensure safety. The Liu laboratory specializes in polymers and polymer composites. Herein we propose two research projects that are suitable for undergraduate students, who can gain extensive research experiences in the synthesis and processing of energetic polymers and polymer composites.

First, we hypothesize that solution-processable high-performance polymers can be modified to generate energetic polymers that are safer than their counterpart 'normal' polymers. To mentor the undergraduate students, we will start with the simplest energetic polymer, e.g., polyurethane. Polyurethane is often used as shoe soles, and if incorporated with energetic moieties, it will become explosive. Then, we will use modification chemistry to functionalize polyetherimide (aka, Ultem) to produce azide-containing polymers. The synthesis chemistry is based upon a recent publication in our laboratory. The amount of azide in polyetherimide is tuned down to ensure undergraduate students’ safety, but the concept remains the same.

Dr. Michael Bortner, Department of Chemical Engineering

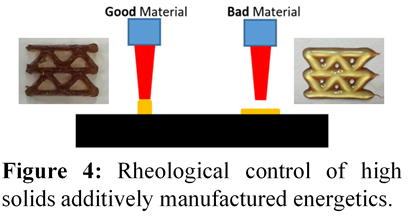

High solids content additive manufacturing offers a unique opportunity to tailor kinetics when incorporating reactive metals and tailored binder chemistries. In Direct Ink Write (DIW) material extrusion additive manufacturing, an extrusion nozzle is translated to directly and selectively deposit material onto a substrate to pattern each layer. The inks used in DIW must be flowable through the nozzle and then solidify upon deposition to keep their shape. While various different solidification mechanisms exist, compositions that are represented as yield stress materials (reactive or not) offer immediate promise for manufacturing of tailored geometry reactive metals systems.

The goal of this research project is to establish how micrometric particle morphology, surface chemistry and composition (in mixed metal systems) impacts the yield stress and flow behavior of metal formulations for DIW printing. While these formulations will practically require a suitable binder for burn rate and related energetic analysis, a representative surrogate matrix material can initially be implemented in this fundamental study on the rheological behavior of the system and translated to representative matrix materials. Understanding the flow behavior is critical to enable additive manufacturing of high solids content formulations and to enable custom geometries and performance. This will answer the hypothesis that the interplay between particle geometry, particle size distribution and particle surface chemistry will significantly impact yield stress and elastic response/control of deposition geometry at comparable compositional ratios in DIW processing of reactive metal formulations. Teaming opportunities for REU students include demonstrating novel high solids content additively manufactured rocket propulsion systems (Young) with high oxygen content polymer binder (Schulz).

TRACK 2: Cutting Edge Experiments and Diagnostics to Put Sharper Focus on Multiphase Reacting Flows

Dr. Greg Young, Department of Aerospace and Ocean Engineering

Metals have been a core ingredient in energetic formulations since as early as the 1950’s (Davis 1963). Recent advances in nanotechnology, additive manufacturing, and processing offer opportunities for greater energetic output and or control of energetic release rates. This is particularly exciting for high-speed propulsion systems enabling new mission profiles. Processes such as additive manufacturing and mechanical alloying result in composite materials that are not well understood and require study of their fundamental properties as well as a determination of their effectiveness as energetic materials or energetic material supplements. To address this, a multi scale approach is proposed utilizing existing infrastructure located within the Propulsion and Energetics Laboratory.

The REU researcher will apply experimental methods to quantify fundamental ignition and combustion properties of novel energetic metal composites and alloys starting at the submilligram scale. This will be accomplished using a high-pressure temperature jump experiment (Figure 5). Students will gain experience with various static and dynamic measurements, optical diagnostics, and advanced optical diagnostics coordinated with the Lowe group. In an iterative process with the Aning and Liu groups, materials may be optimized for study at larger scales. The combustion of newly developed energetic composites and alloys in high enthalpy flows encountered in rockets and or ramjets will be explored with the energetic output compared to traditional metals of interest such as aluminum, boron or magnesium. The incorporation of these materials in polymers developed by the Shulz group or processes developed by the Bortner group may also be explored. The ultimate goal of the project is to develop an understanding of the fundamental combustion characteristics of newly developed energetic composites and alloys as well as their behavior in high enthalpy flow fields. The potential outcome for the REU student includes gaining experience in laboratory combustion experiments including advanced diagnostics, fuel and or propellant formulation and processing, as well as practical applications.

Dr. Eric Jacques, Department of Civil and Environmental Engineering

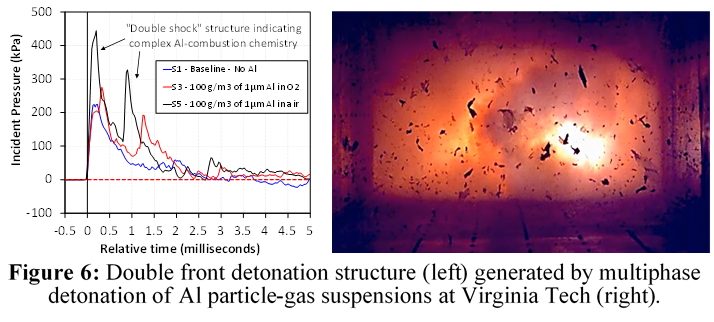

Heterogeneous mixtures of combustible gases and suspended energetic particles can undergo a unique two-phase double front detonation (DFD) (Figure 6). The DFD structure is characterized by an initial gas phase detonation wave that is reinforced some time later by a second shock front caused by heating and volumetric expansion from particle combustion (Veyssière and Khasainov 1991). Particle kinetics play an important role, as do the physical processes of shock-interactions, mixing, and particle collision, which govern the mechanisms involved in the mass, momentum, and heat transfer between solid and gas phases (Zhang et al. 2004). However, the combustion modes of reactive metal particles suspended in combustible gases has not been thoroughly established (Zhang et al. 2009) because performing the necessary experiments at the appropriate time and length scales is difficult, even in well-equipped labs (Gordopolov et al. 2009). Most work in this area has focused on suspensions of micrometric aluminum particles (e.g., Tulis and Selman 1982; Veyssière 1986), and data on the DFD structure produced by other reactive metals are scarce.

The REU researcher will experimentally probe features of the detonation structure of reactive metal suspensions using the Virginia Tech Shock Tube Research Facility to generate multiphase explosions. The large-scale experiments will involve bulk particle-gas mixtures, with mass loads ranging from 10s to 100s of grams of metal powders, subjected to the detonation products of gaseous acetylene-oxygen. The researcher will learn to apply advanced piezo, ionization, and optical diagnostics to correlate the spatiotemporal variation in pressure, gas phase flame front, and solid phase particle combustion kinetics with the theoretical structure of DFD. The existence of the DFD propagation regime will be explored as a function of the mass concentration of commercially available reactive metal powders, including Aluminum as well as other reactive metals (e.g., Mg, Ti, Zr) that have not previously been studied. Collaboration with REU student in the Aning group will focus on DFD structures in metastable alloy suspensions, such as Al-Mg or B-Ti. Integrating the flow visualization techniques developed by the student in the Lowe group could reveal previously unseen features of the propagation regime. Ultimately, this work aims to advance our understanding of DFD by providing a critical framework for correlating the features of the detonation structure of heterogeneous particle-gas mixtures as a function of the mass concentration of various reactive metals.

Dr. Gary Seidel, Department of Aerospace and Ocean Engineering

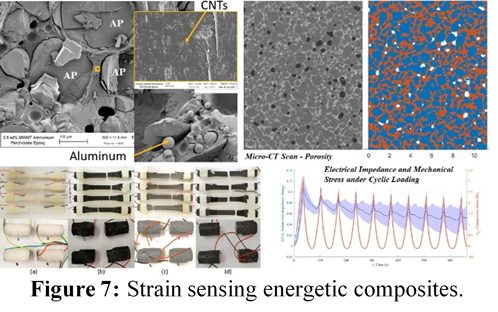

This research hypothesizes that there is an optimum amount of carbon nanotubes to disperse within a solid rocket fuel that provides optimum mesoscale strain, damage, and temperature sensing from within the composite. Embedded sensing in energetic materials serves as a breakthrough technology for both diagnostics and development applications as well as for safety in operations and handling (Shirodkar et al. 2019). This form of structural health monitoring technology (Figure 8) can aid in understanding of the formation of hot-spots and their effects on sensitivity as a result of the mechanical insults or vibration loads during transport, or can be applied in measuring the propagation front in new energetic formulations.

REU researchers will fabricate propellant mixtures consisting of ammonium perchlorate dispersed in an elastomeric binder containing aluminum microparticles. In later years, metastable alloys prepared by REU students working in the Aning group, could be substituted for elemental aluminum. In addition, the aluminized binder will be enriched with varying concentrations of carbon nanotubes. The carbon nanotubes produce an electromechanically coupled piezoresistive network which is sensitive to deformations induced by thermo-mechanical loading as well as thermoresistive response which is directly sensitive to temperature changes (Rocker et al. 2017; Shirodkar et al. 2018). However, there are questions as to how the piezoresistive network interacts with the conductive aluminum particles also dispersed in the binder. Students will conduct thermomechanical testing to measure the gauge factor corresponding to various carbon nanotube concentrations within the aluminized energetic material. Testing will include both direct tension and compression to failure tests as well as compression-compression low frequency cyclic testing. This program builds on the expertise of the Jacques group in response of materials and structures to external loads (Jacques and Makar 2019). Some of these tests will be conducted at elevated temperatures within an environmental chamber mounted to the mechanical testing frame. Once the thermomechanical testing of the samples is complete, the samples will be destroyed via burning wherein we hope to observe any effects the carbon nanotubes have on the rate of consumption, and possibly collaborate on direct measurements of the products.

TRACK 3: Towards Greater Insights on Applications of Modeling and Machine Learning in Metallized Energetics

Dr. Luca Massa, Department of Aerospace and Ocean Engineering

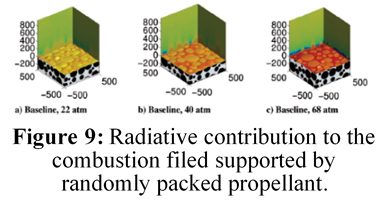

Aluminum is omnipresent in reactive materials for a variety of reasons, including acoustic stabilization and increased impulse. Yet its importance to heat transfer is not well understood. Both of these phenomena take advantage of the large heat release of the aluminum oxidation reaction in the gas chamber and do not relate to the propellant burning. Experimental investigations by Dokhan et al. (2003) showed that adding a small volume fraction of nanoscale aluminum to solid propellant has a profound impact on the burn rate and the heat transfer to the flame. Experiments on propellant packs (Stephens et al. 2005) found that increasing the Al size greatly decreases the burn rate. Using a simplified radiation model, Massa and Jackson (2008) found that that the contribution of radiation to the feedback from ultrafine aluminum is substantial and pressure dependent, and yields flatter propellant surfaces (Figure 9). Therefore, a fundamental open question is how the particle size and chemical composition change the contribution of radiation to the burning of the metals.

The REU researcher will focus on extending an adaptive Ray-Trace algorithm for reactive media to model the combustion chemistry of Aluminum, initially and then extending to other metals, with a polydisperse particle distribution that includes both Lagrangian and Eulerian particles. Comparison with REU students performing propellant (Young) and detonation experiments (Jacques) using materials synthesized by students in the Aning, Schulz, Liu, or Bortner groups is anticipated to reveal the effect of particle size, distribution, and chemistry on the convective and radiative heat transfers. We will separate the contributions of reaction exothermicity and photon emission. A parametric analysis will identify how the ratio changes with fluid regime and particle distribution. A python script will be used to interface numerical simulations of radiative ray tracing with large scale combustion models carried by the Massa graduate’s research group.

Dr. Todd Lowe, Department of Aerospace and Ocean Engineering

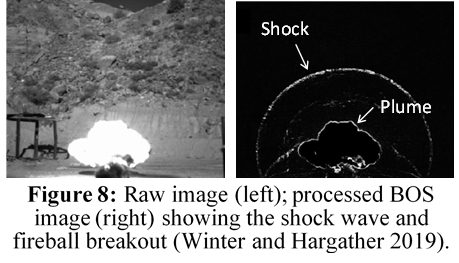

Revealing the details of reactions in energetic materials has the potential for guiding discovery of fluid dynamics and kinetics mechanisms that could significantly advance research. While currently at an impressive state, the challenges of direct simulation of these phenomena make experimental study the only viable approach for understanding many of these mechanisms. But experiments have their own challenges with measurement of extremely rapid and complex events. In the proposed effort, the REU researcher working in the Lowe group the REU students working with Jacques and Young to support their fundamental studies of energetic materials, while advancing fundamental research in quantitative flow imaging. Time-resolved imaging will be used to obtain quantitative visualizations of density structures using background oriented schlieren imaging (BOS) (Elsinga et al. 2004, Raffel 2015). The results, such as those seen in Figure 8 from Winter and Hargather (2019), can reveal entropy structures, variations in species (both in “Plume”), and shock or acoustic phenomena (labelled “Shock”). Basic research is needed to develop fundamentally sound methods to separate these contributions in schlieren images: an excellent opportunity for impact by the REU students. In the research project, students will first learn the fundamental aspects of measurement such as uncertainty, interfering inputs, and basic statistics. Next, the basics of high-speed imaging and image processing will be covered through experiential learning in the laboratory, including mentorship from graduate students. The project will culminate with basic efforts at data interpretation in collaboration Jacques and Young, and will cover both the advances in measurement and understanding of energetic reactions.

Dr. Rodrigo Sarlo, Department of Civil Engieering

REU researchers will study the use of machine learning with computer vision to automatically process time-sequenced images and characterize detonation or rocket firing events and detect anomalies. Raw images of energetic events will be collected using high-speed photography, hyperspectral imaging, and optical pyrometry performed by students in the Jacques and Young groups. Students in the Lowe group will process the raw images to aid in the visualization of key entropy structures (e.g. plume, shock wave). From here, the researchers working in the Sarlo group will develop a probabilistic graphical model (PGM) to process each image in sequence and label the areas corresponding to each event. A PGM is chosen because it has been used in the past to track objects in image sequences, incorporating a priori expert knowledge (Beal et al. 2002). This both reduces the need for training data and improves performance. Finally, via machine learning, the tool will extract key features from each event, including width, shape, color, rate of change, and others. The features will be used to predict characteristic parameters of the energetic event, such as total energy output, temperature, etc. These will be compared to a “ground truth” physical model to identify physical anomalies in a completely automated fashion. REU students will learn the basics of graph structures and how they can be used to model physical phenomena such as detonations and two-phase flow (Tan, 2018). The students will also learn introductory techniques for feature extraction from images using simple machine learning models.